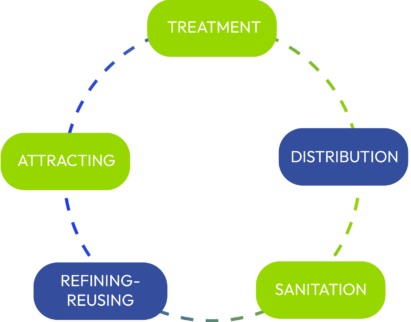

Leading the digitisation and control of the water cycle with innovation and cutting-edge technology

Grupo Amper has more than 30 years of experience in the field of Digitalisation and Control of the water cycle, always in search of efficiency and productivity in all types of industrial processes. It incorporates the latest technologies on the market, with a great innovative vocation and a continuous search for technological advances.

Context and challenges of the digitisation of the water cycle

The digitised management of the water cycle presents many challenges, such as managing the large amount of data and variables to analyse and the scarcity of resources to do so, the analysis of databases and SCADA systems, the reduction of operational costs, the difficulty of informing the user due to the type of meters, the unbilled water and its uncontrolled losses.

Reduce costs, reduce carbon footprint and improve efficiency with our solutions

The benefits of smart water cycle management include reduced water and energy costs and therefore carbon footprint (up to 21%), reduced maintenance operations, increased network security by avoiding overpressure in adverse weather conditions, improved reliability and quality of service through Digital Twins in water supply and sewerage networks, improved irrigation management and reduced environmental impact.

Control centres for water transport and distribution networks, with the use of tools that allow, through systems such as SCADA or GIS, the detection of leaks, overconsumption or water quality problems in real time.

System automation systems, drinking water treatment plants (DWTPs), wastewater treatment plants (WWTPs), pumping stations, etc.

IoT instrumentation and sensors, which make it possible to monitor and control each and every one of the water cycle management variables: quality parameters, limnological parameters, pumping and process consumption, pollutant load, industrial discharge parameters,

Artificial Intelligence and Decision Support Systems (DSS)

1. With advanced analytics and artificial intelligence (Digital Twins and Machine Learning), using machine learning algorithms to forecast and predict future water and energy demand, taking into account factors such as weather forecasts and nightly water consumption rates.

2. Asset monitoring in a simple and unified way, without the need for different tools or independent platforms.

3. Optimisation of pumping elements by generating optimal control parameters for the control of valves and pumps in real time, by integrating factors such as electricity prices, hydraulic constraints and the availability of renewable energy sources.

Artificial vision that also allows us to control the type of bacteria and microorganisms and thus ensure correct treatment in the purification phases.